Turn Raw Materials into Functional Parts with Our Value-Added Capabilities

Optimize your supply chain by reducing steps and eliminating costs. Our extensive list of finishing and fabrication capabilities helps to reduce the number of outside vendors and minimize freight and queue time to get quality parts on time and within a budget.

Saw Cutting

Clean and Accurate Cuts Every Time

Receive your materials cleanly cut to accurate lengths through our saw-cutting capability. With high production rates and reduced handling, our saw-cutting service saves you critical production time and reduces the risk of accidents.

EXPLORE SAW CUTTING

Laser Cutting

One and Done Strategy

Our state-of-the-art tube lasers can quickly and accurately cut simple to complex shapes into a wide variety of sizes and lengths. With Tubular Steel’s laser cutting capabilities, you can minimize the handling, production steps, and soft costs associated with processing material on your shop floor.

EXPLORE LASER CUTTINGCNC Machining

Complex Machinery Held to Tight Tolerances

Our manufacturing experts fabricate your parts using high-quality materials with the latest machine technology to provide you with the tight tolerances your operation requires. Our expertise in milling, turning, boring, threading, and more allows us to support you beyond the material we supply.

EXPLORE CNC MACHINING

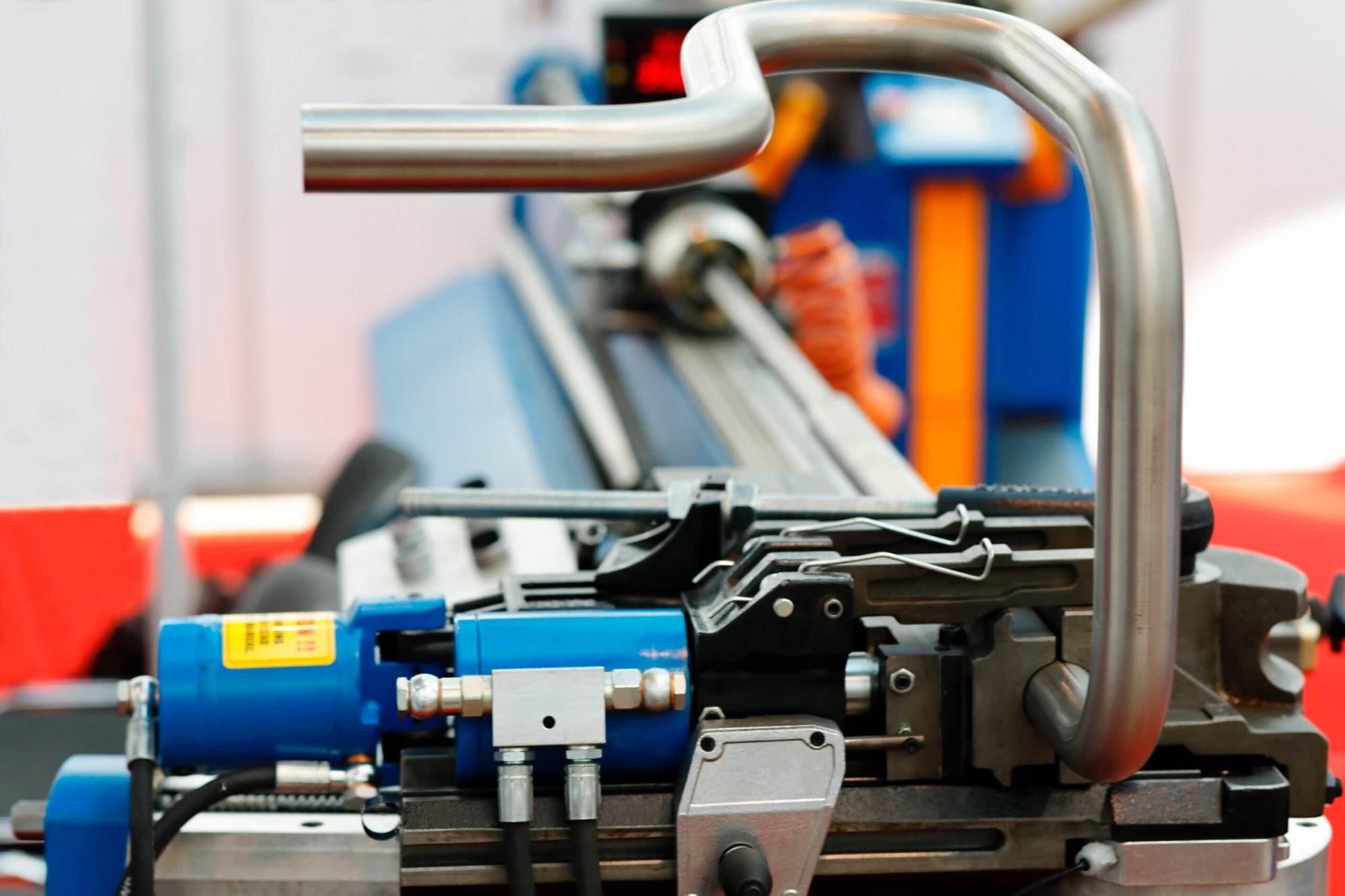

CNC Tube Bending

Versatile and Precise Tube Bending Solutions

We use CNC tube benders to produce accurate and repeatable bends in metal pipes and tubes of various sizes and lengths. These highly automated machines ensure your parts are both cost-effective and precise.

EXPLORE CNC TUBE BENDINGFinishing

Ensure Your Parts Are Ready to Run Right Out of the Box

Whether you are finishing the parts yourself or assembling them directly into your end product, our extensive list of finishing services allows you to save time and money. With surface prep, powder coating, plating, and more, receive your materials and put them to work right out of the box.

EXPLORE FINISHING